History, Mission, Activity and Certifications

Delta Engineering was founded at the beginning of the 80’s. The industrial market is its natural home with particular attention to the piping sector.

In 1992 it takes the first critical step, Delta Engineering buys the Cosmec srl company certified ISO 9001; U-stamp and S-STAMP and thanks to this acquisition in terms of human resources and workshop equipment it becomes, in a short time, leader in Pressure Vessel market in Italy.

In middle of the 90’s Delta Engineering passes on to a second phase and creates the “Filtration Department”. In 2000 Delta Engineering buys SITECO; thanks to this acquisition Delta Engineering acquires the engineering activity for process packages focalized for Petrol-chemical industry; Power Generation & Gas Treatment.

In 2005 it expands its activity in Europe and North Africa and Delta Engineering enters in a short time in Spain, Algeria, Libya, Egypt. Now Delta Engineering steadily supplies Gas & Water Treatment Packages.

In 2012 Delta Engineering buys Elfor Controls,

a company specialized in the production of pneumatic,

hydraulic and electric valves actuators.

In more than 30 years Delta Engineering srl has proved

its flexibility and capacity to anticipate and meet the

market requests. With this same spirit we look to the

future focusing on our background and know-how.

- Design & Engineering

- Project Management

- Manufacturing

- Quality

We will earn our customer’s TRUST; we will demonstrate superior levels of

FLEXIBILITY; and we will deliver Oil & Gas process equipment packages,

systems, and services of the highest QUALITY.

It is our goal to make every customer a repeat customer.

Ing. Pietro Baldini, President

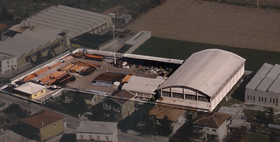

Starting from Process and Technical Design, passing through the

Project Management and thanks to the Manufacturing capabilities,

Delta Engineering is able to provide a complete service focused on

customer satisfaction.

.

- Trust

- Flexibility

- Quality

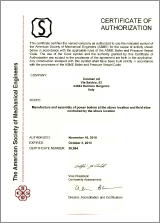

ISO 9001

U Stamp

U2 Stamp

S Stamp

FPAL

Re Pro

CEoqs