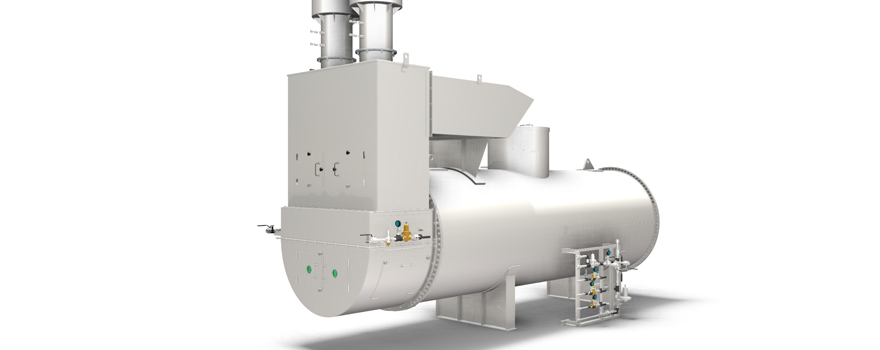

Heaters

Indirect type

Product Overview

Indirect Bath Heaters have a wide variety of successful applications in the oil and gas production, processing and trasmission industry. Some of the most common application include the following:

Housing Material

- Gas Dew Point Heating: high-pressure natural gas heating upstream pressure regulation stations preventing condensation phenomena due to the Joule-Thomson effect.

- Heating of high-pressure natural gas upstream pressure regulation in order to prevent external icing formation.

- Fuel gas super-heating upstream gas turbines (Performance haters)

- Gas Heating downstream low temperature storages.

- Hydrate prevention.

- Viscosity reduction: Crude Oil Heating upstream treatments to facilitate degassing and dewatering.

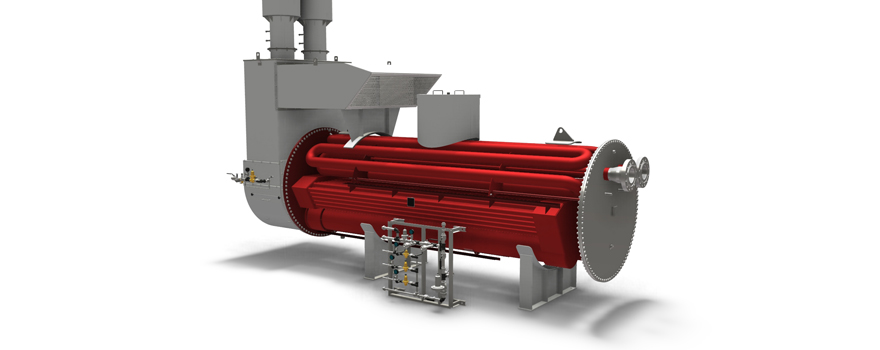

Main components

Indirect Bath Heaters are composed of the following main parts:

- Shell

- The coil or tube bundle

- The water expansion tank

- The fuel feed line

- Burner (gas type, oil type or bi-fuel)

- Removable fire-tube

- Chimney

- Burner management system panel

- Skid frame and service platform

- Insulation

- Instruments

Main features

The heater shall contains the fire-tube that allows

a rapid heat transfer (both radiant and convective)

from the flame to the hot medium. The heat is

transferred from the bath to the coil/tube bundle

and then safely to the gas or the oil.

The expansion tank allow the hot medium to be

contained for the thermal expansion due to the

temperature increase.

Level gauges and transmitters advise when

additional water or hot medium is required and

give alarms in case of overfilling.

Range

The duty of Delta Engineering heaters can vary from 90Kw to 10 Mw