Heat Exchanger

Shell & Tube Heat Exchanger

Product Overview

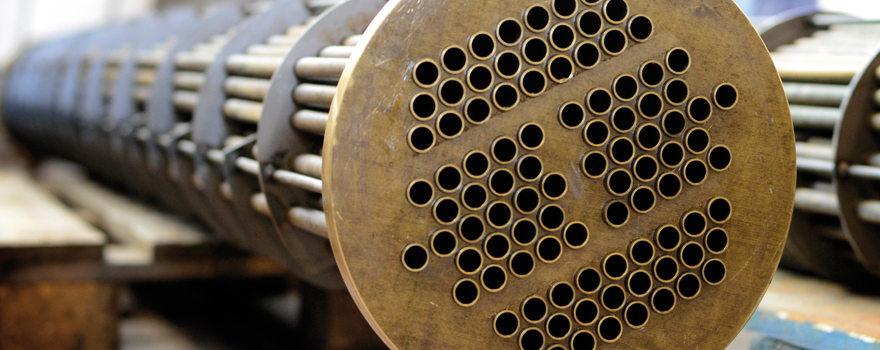

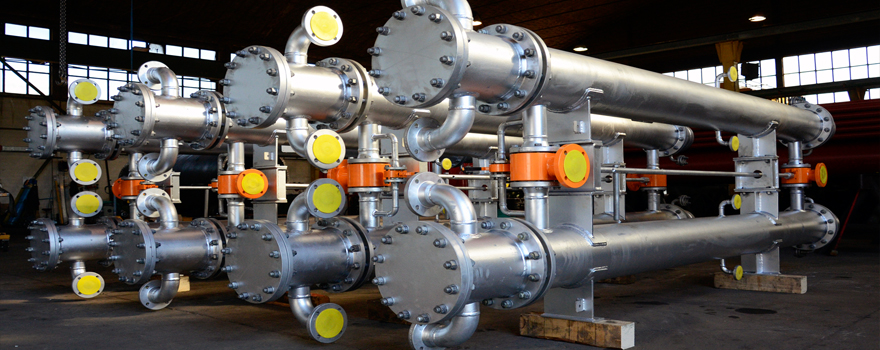

Shell and tube heat exchangers consist of a series of tubes. One set of these tubes contains the fluid that must be either heated or cooled. The second fluid runs over the tubes that are being heated or cooled so that it can either provide the heat or absorb the heat required. A set of tubes is called the tube bundle and can be made up of several types of tubes: plain, longitudinally finned, etc. Shell and tube heatexchangers are typically used for high-pressure applications This is because the shell and tube heat exchangers are robust due to their shape. There are several thermal design features that are to be taken into account when designing the tubes in the shell and tube heat exchangers.

Application

- Tube diameter: Using a small tube diameter makes the heat exchanger both economical and compact. However, it is more likely for the heat exchanger to foul up faster and the small size makes mechanical cleaning of the fouling difficult. To prevail over the fouling and cleaning problems, larger tube diameters can be used. Thus to determine the tube diameter, the available space, cost and the fouling nature of the fluids must be considered.

- Tube thickness: The thickness of the wall of the tubes is usually determined to ensure: There is enough room for corrosion That flow-induced vibration has resistance Axial strength Availability of spare parts Hoop strength (to withstand internal tube pressure) Buckling strength (to withstand overpressure in the shell)

Construction materials

- Carbon Steel

- Stainless Steel

- Naval Brass

- Admiralty

- Titanium