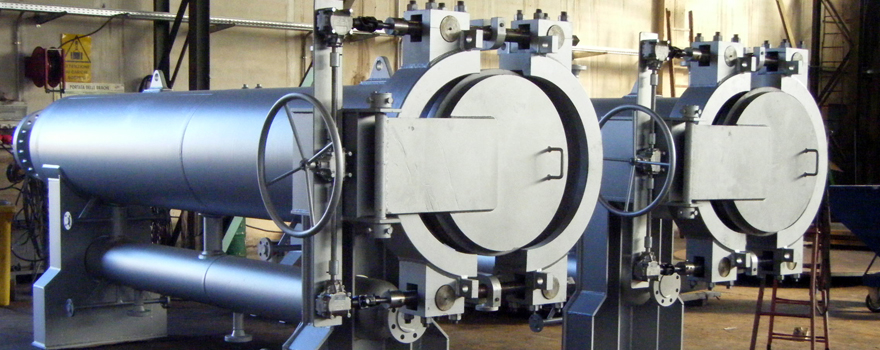

Double Barrel

NATURAL GAS FILTERS

Product Overview

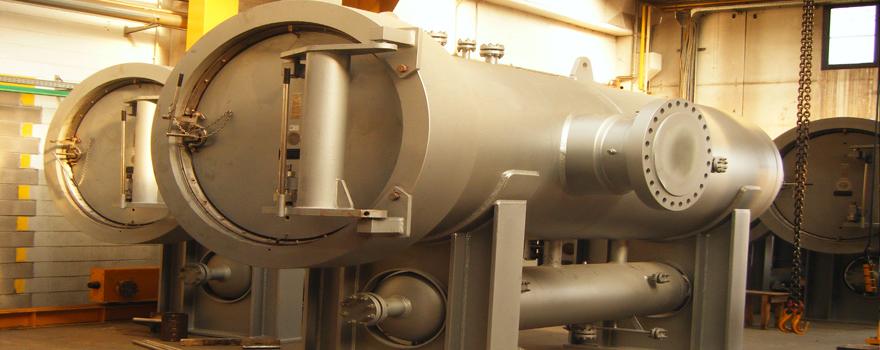

Filter separator ara available in horizontal and vertical orientation, with horizontal the most common. This type of separator is often used for solids and liquid removal in relatively low liquid loading application. A filter separator is a two stage device. Gas enters the inlet nozzle and passes through the filter section, where solids particles are filtered from gas stream and liquid particles are coalesced into larger droplets. Any free liquid are also removed in the first section. The coalesced droplet pass through the filter riser tubes and carried into the second section of separator, where a final mist extraction element removed these droplet from the gas steam.

Flow through the filter elements is from outside to inside direction. A pressure drop of 7-14 kPa is normal in a clean filter separator. If solids are present, it will normally be necessary to replace the filter elements at regular intervals. A 70 kPa pressure drop criteria is often used for filter changeout. Removal of the filter is achieved via quick-opening closure.The second stage of a filter separator contains a mist extractor device. As for conventional separator this may be a mesh pad, vane pack or multicyclone bundle. Mesh pad and vane pack are most commonly utilized.

INTERNALS

- Cartridges

- Nesh Pads

- Vane Pack